Managing consignment inventory in Dynamics 365 Finance and Operations provides organizations with a powerful way to optimize stock levels, enhance cash flow, and mitigate the financial risks associated with holding inventory. When paired with advanced warehouse management, it delivers enhanced visibility, accurate tracking, and automated processes for seamless ownership transitions.

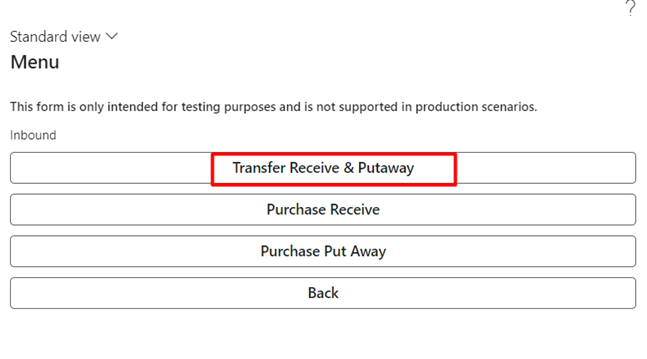

In this guide, we’ll break down what consignment inventory is, its key benefits, and provide a practical example of receiving goods from a vendor into a non-WMS warehouse before transferring them to a Dynamics 365 advanced warehouse management (WMS-enabled) environment.

You’ll also discover step-by-step instructions on how to account for consignment inventory, as well as best practices for integrating it with advanced warehouse management systems to achieve maximum efficiency.

What is consignment inventory?

Consignment inventory is a supply chain model in which goods are stored at the buyer’s location but remain the legal property of the supplier (or vendor) until they are sold or consumed. In consignment inventory accounting, this means the stock stays on the vendor’s books until ownership is formally transferred to the buyer.

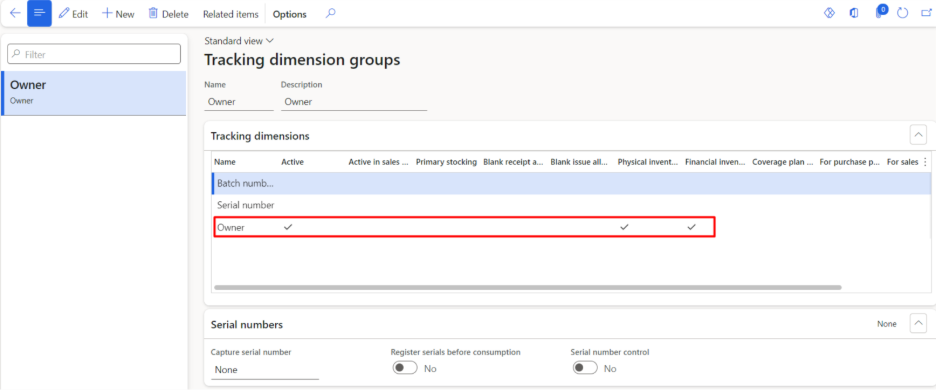

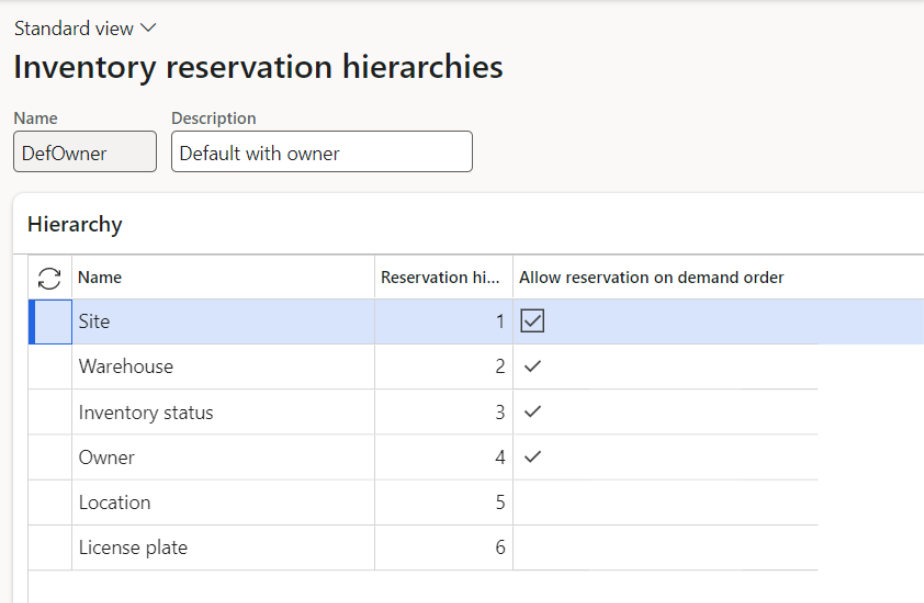

In Dynamics 365 Finance and Operations, consignment inventory is managed through:

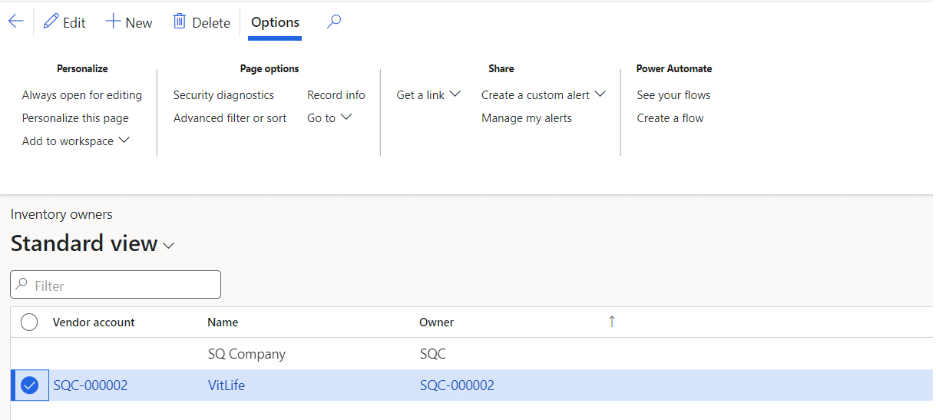

- Inventory ownership dimensions

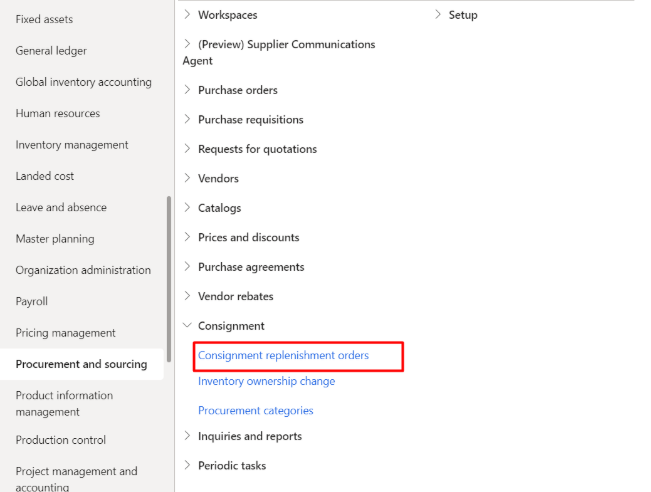

- Consignment replenishment orders

- Inventory ownership journals

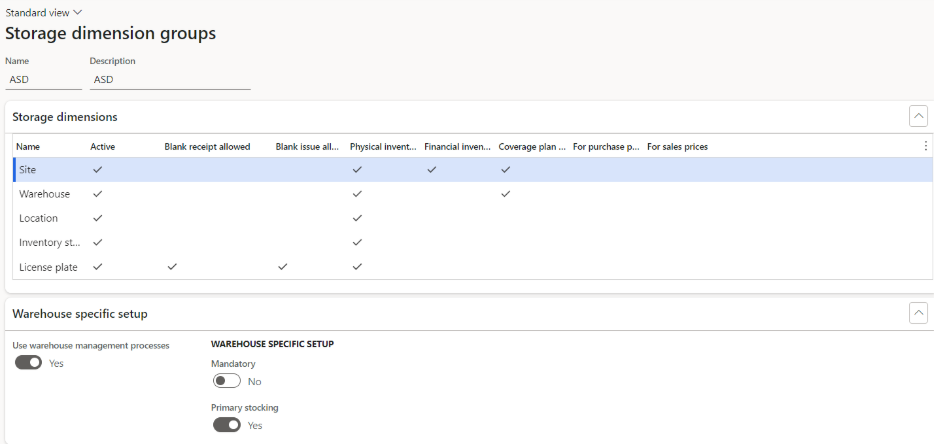

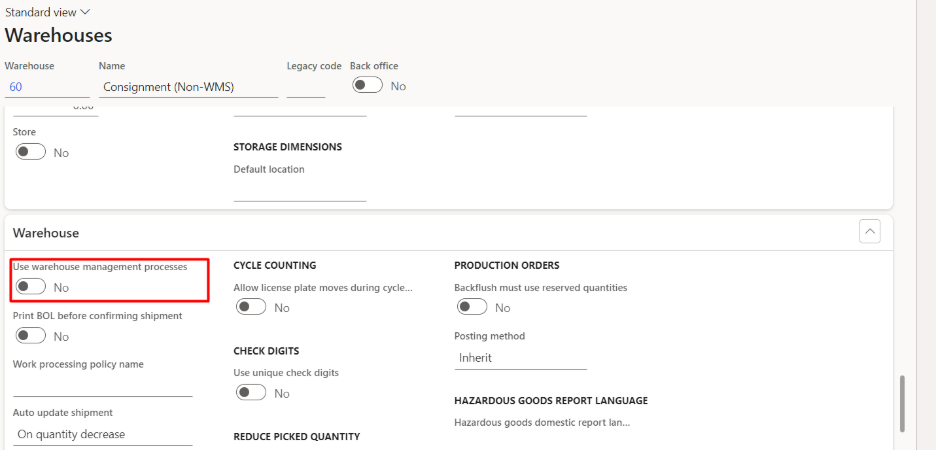

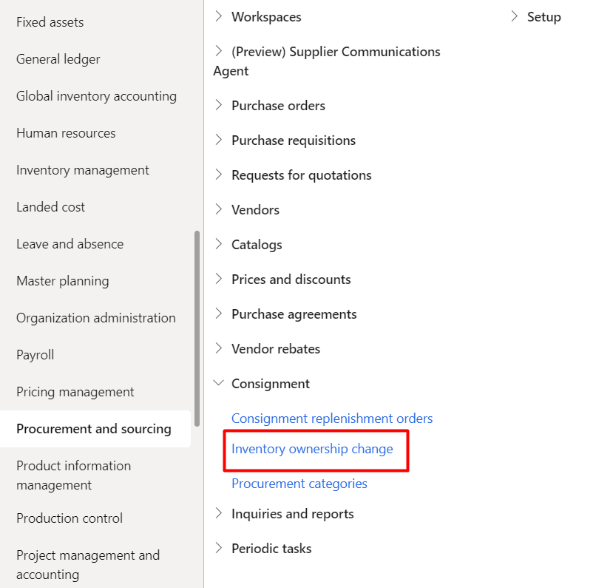

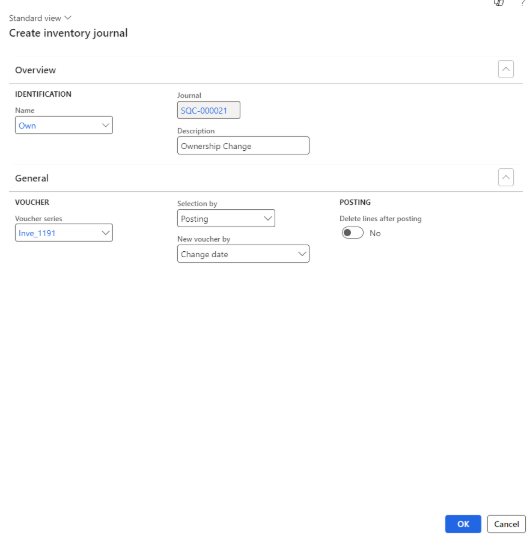

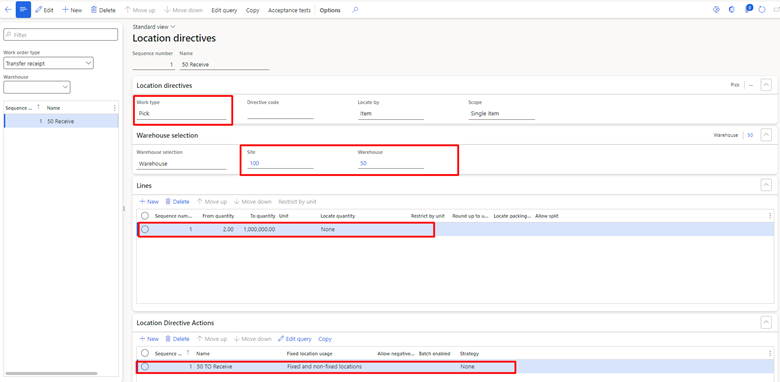

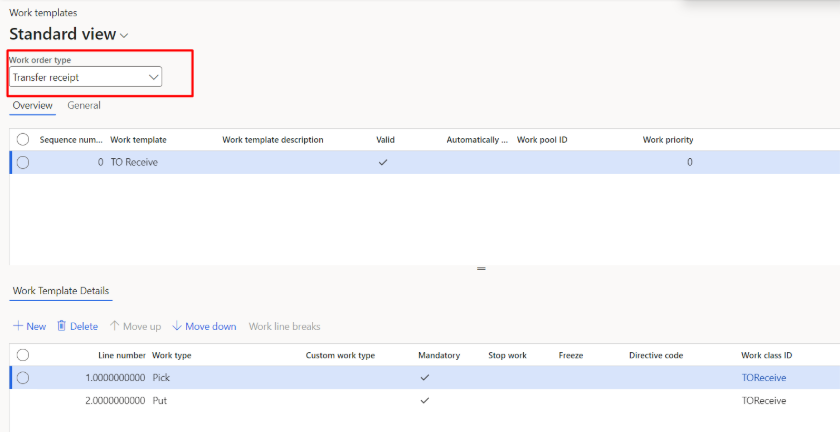

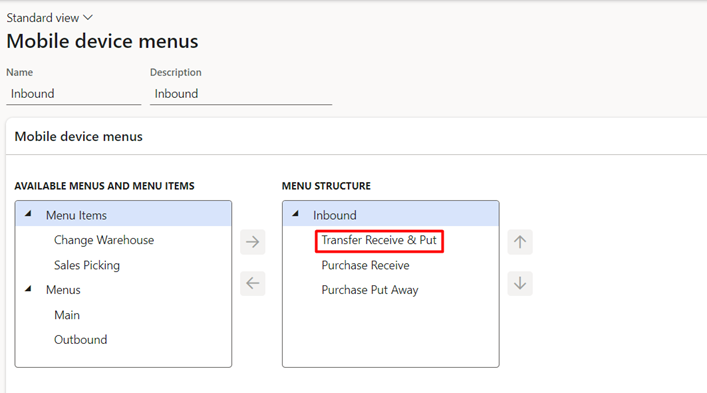

Important to note: The standard consignment inventory process in D365 is not directly compatible with advanced warehouse management in Microsoft Dynamics 365 Finance and Operations. To ensure smooth integration, the best practice is first to receive goods into a non-WMS warehouse, transfer ownership to your company, and then move the inventory into a WMS-enabled warehouse using transfer orders.

Read more: How to set up consignment inventory in D365 F&O?

Key benefits of using consignment inventory for a smarter supply chain

Managing inventory effectively is crucial to maintaining smooth operations and achieving profitability. Consignment inventory not only minimizes upfront investment but also enhances visibility and collaboration across the supply chain, making it a valuable approach for businesses of all sizes.

Let’s explore its benefits across industries:

1. Improved cash flow

One of the key benefits of consignment inventory is the ability to pay for stock only after it is consumed or sold. This significantly improves cash flow by freeing up capital for other business operations and investments, allowing companies to operate more flexibly without tying up funds in unused inventory.

2. Lower carrying costs

Since ownership remains with the vendor until consumption, buyers avoid costs like insurance, taxes, and depreciation. This not only reduces operational expenses but also minimizes consignment inventory accounting complexity, as the stock stays off the buyer’s books until ownership changes hands.

3. Reduced risk of obsolescence

With the option to return unsold goods or adjust future orders, businesses can respond quickly to changes in demand. This is especially valuable for perishable items or high-value products, where holding excess inventory can lead to significant financial loss.

4. Better stock availability

Vendors have a vested interest in keeping adequate inventory levels at the buyer’s premises. This helps minimize stockouts, ensuring production continuity or steady sales flow, and strengthening overall supply chain reliability.

5. Stronger vendor-customer relationships

By sharing responsibility for stock management, vendors and customers can build trust and long-term partnerships. This collaborative approach often leads to better communication, faster problem-solving, and mutually beneficial agreements.

6. Streamlined replenishment

Modern operations often use the best consignment stock inventory management software to automate replenishment. By tracking real-time consumption, these systems ensure that stock is replenished efficiently, reducing the need for manual intervention.

7. Accurate vendor forecasting

With direct access to real-time usage data, vendors can forecast demand more accurately. This helps optimize production schedules, reduce lead times, and maintain consistent product availability.

8. Financial reporting advantages

From a reporting standpoint, consignment inventory accounting keeps stock off the buyer’s balance sheet until it is consumed, improving capital efficiency. For example, you can enhance your healthcare industry capabilities with consignment inventory management by keeping essential medical supplies on hand without inflating reported assets or capital expenditure.

Consignment inventory management with Advanced Warehouse in D365 F&O: A business scenario

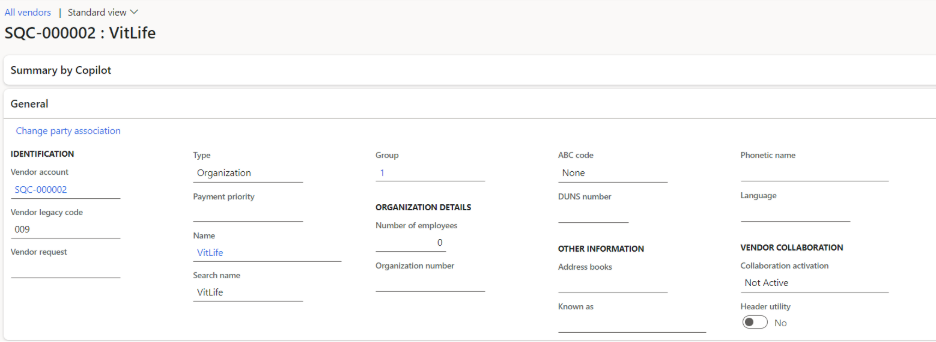

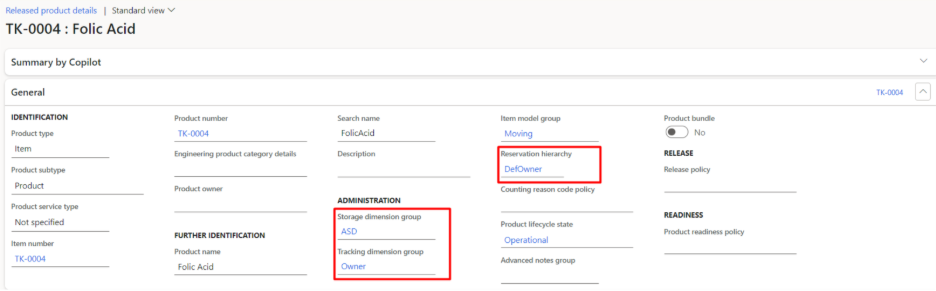

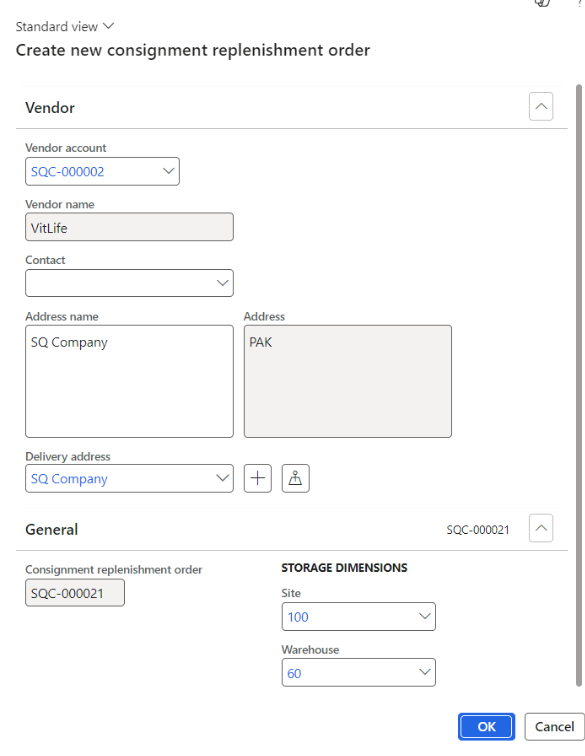

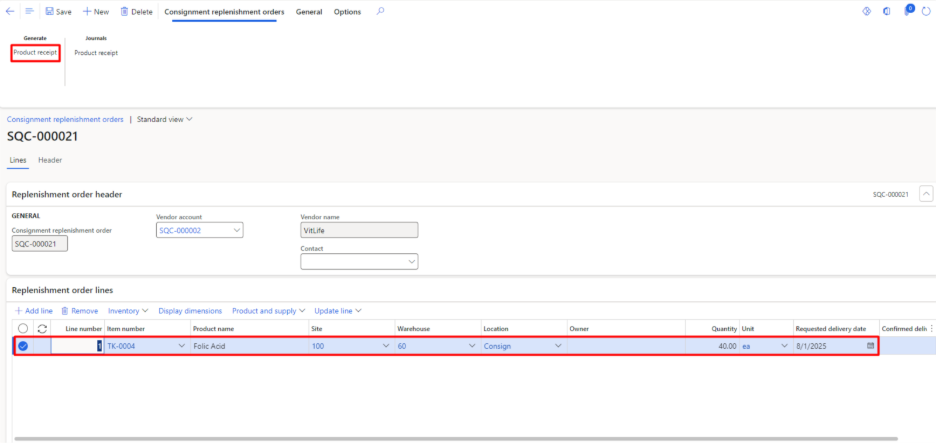

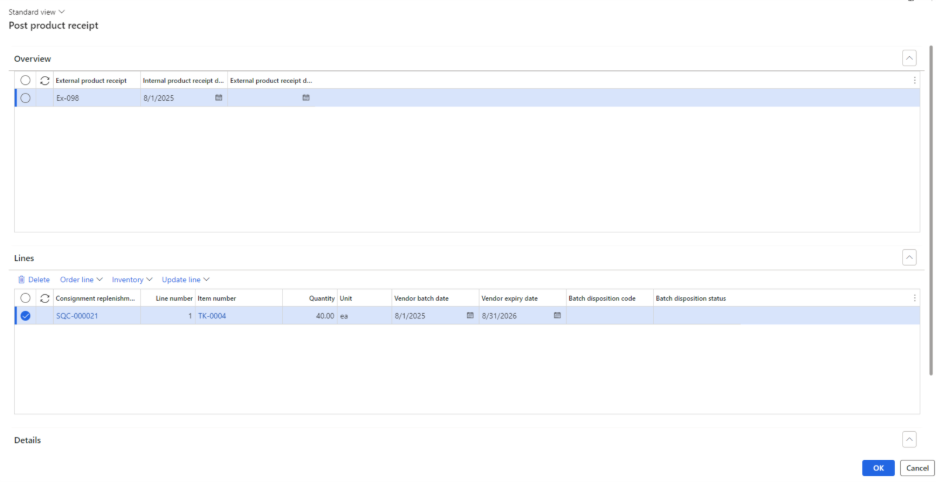

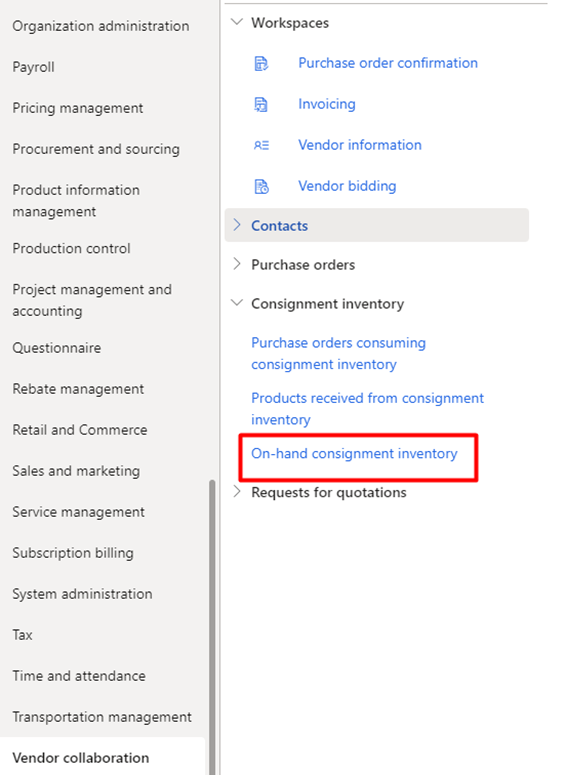

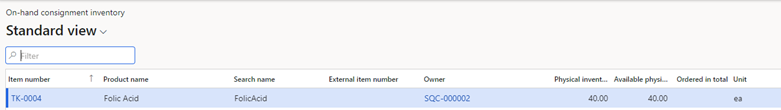

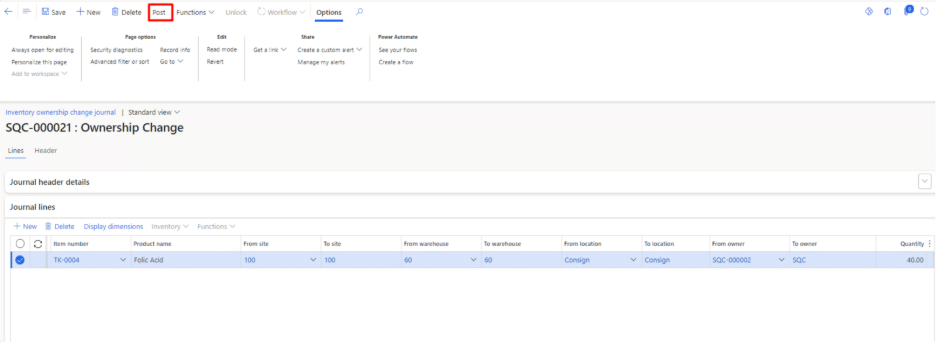

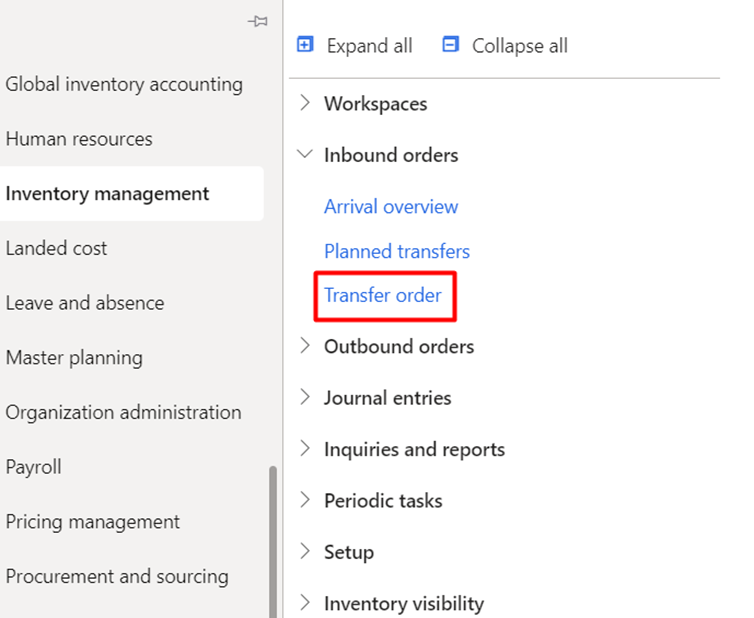

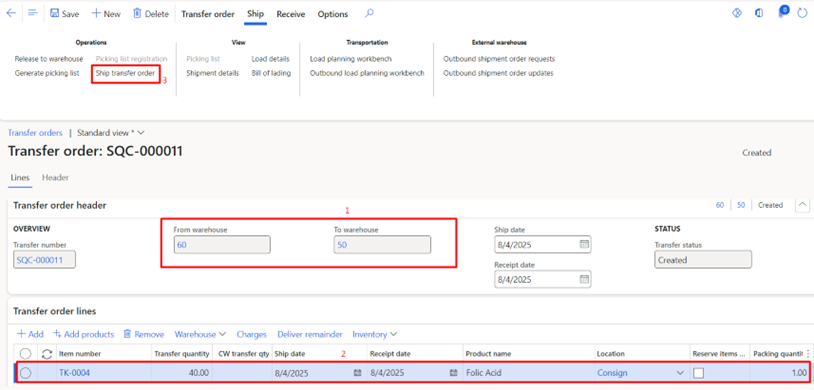

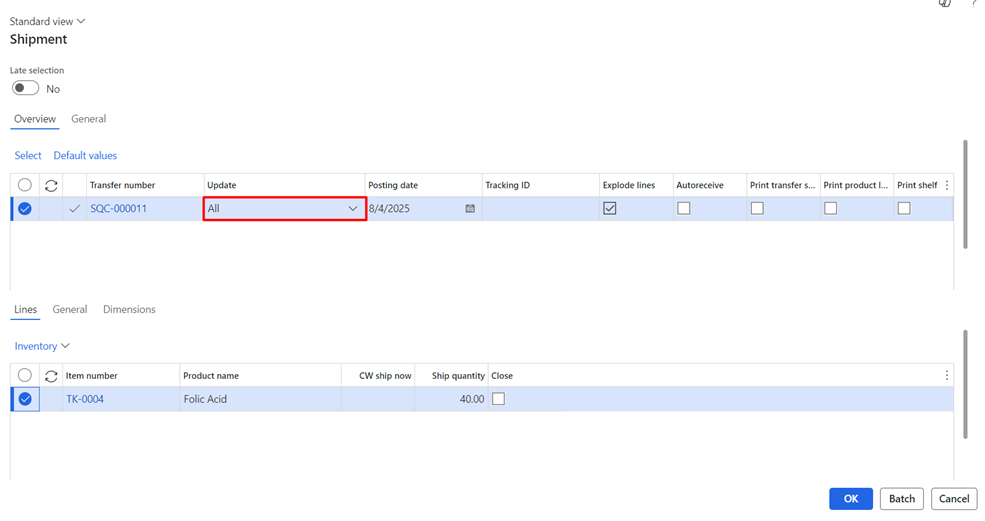

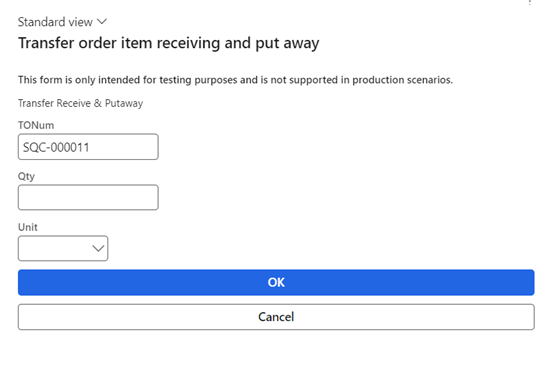

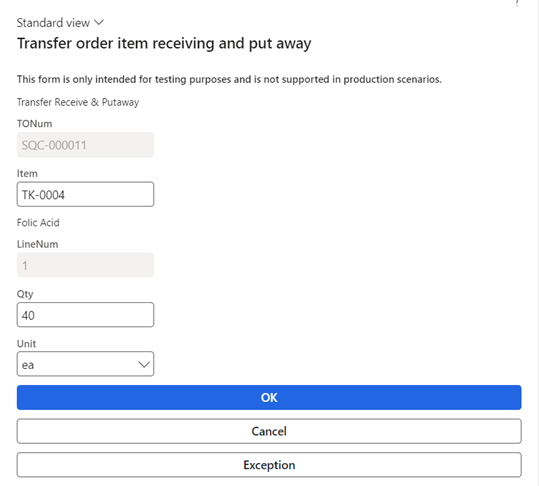

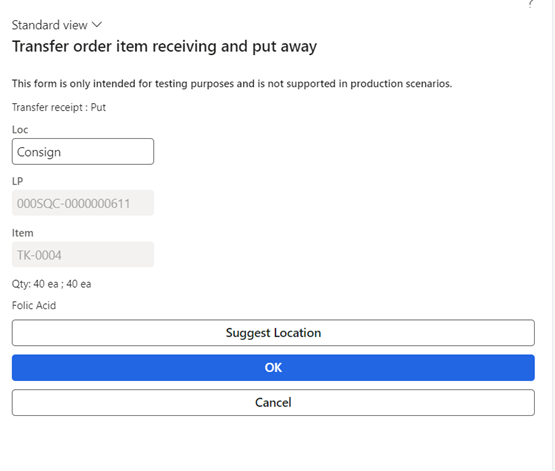

Consider a real-world consignment inventory example involving Folic Acid (TK-0004), sourced from the vendor VitLife. In this scenario, the goods are initially received into a non-WMS warehouse to align with the standard consignment inventory process in Microsoft Dynamics 365.

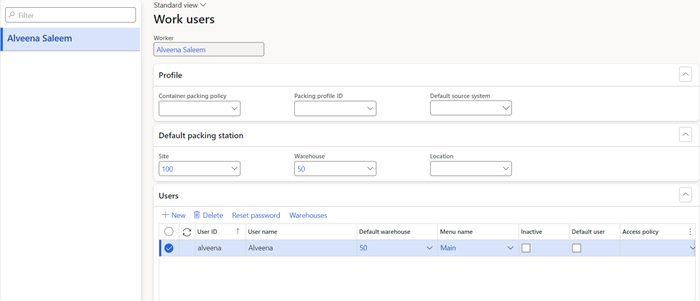

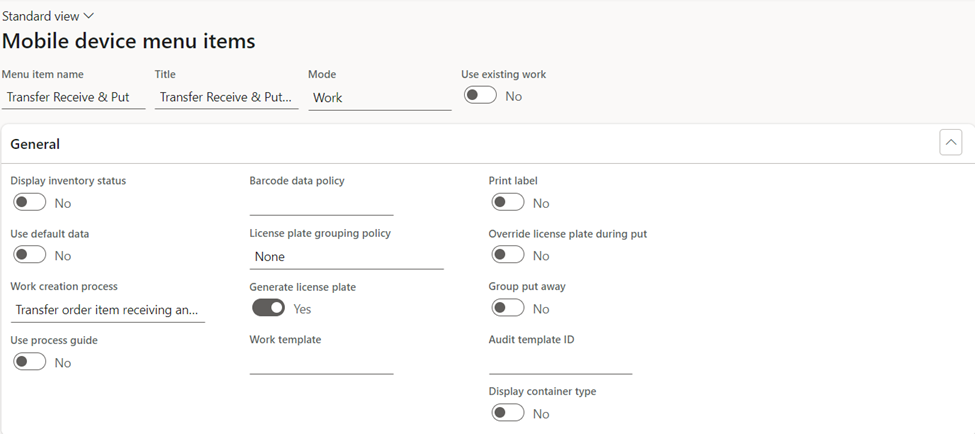

After receipt, the ownership is transferred from the vendor to the company, and the stock is then moved into a Dynamics 365 Advanced Warehouse Management (WMS-enabled) facility. This transfer enables seamless integration with Advanced Warehouse Management in D365 F&O, allowing for automated workflows, accurate tracking, and optimized stock handling.