Production Series – Part 3 by Ali Danish (ERP Microsoft D365FO Solution Architect | Corporate Trainer)

“Every morning in the corporate world, a consultant wakes up and decides whether he will be a billable or a nonbillable resource today. If he is billable, he will add value or not. For me, a true value-added digital transformation is successful if all the stakeholders in the organization are enjoying the daylight with family or friends. Trust me, it’s a blessing to reach home at 4 PM. Apologies for being such a spoiler.”

Before you all get teary-eyed, let us jump to the agenda.

Top Floor: A manufacturing world top floor is referring to the people who are directing the show. The operations director, planning director, or manager are the key resources for the top floor. They are responsible for analytics, planning, forecasting, and defining the KPIs for the production resources.

Shop Floor: A shop floor is a manufacturing facility where assembly or production is carried out, either by an automated system or by workers or a combination of both. The shop floor may include inventory, equipment, workers, etc. It’s an area in the facility where things are made physically.

Then, what does the production manager do?

The production manager is coordinating and bridging the gap between the top floor and the shop floor. The production manager is responsible for production units and the production process.

The production manager is the process owner for the shop floor. Once the production order is started, the material and resources are consumed, till the production order is ended, the shop floor or production manager owns all these activities.

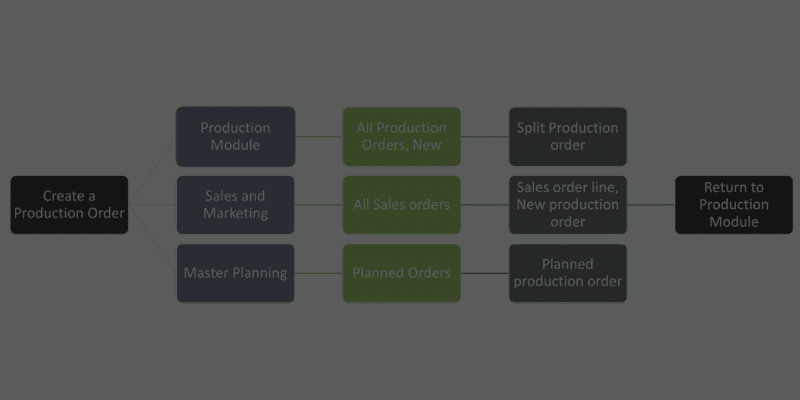

In this blog, we will create the production order manually from the Production module. We will discuss the production lifecycle and steps involved in the production along with the scheduling options that are available in Microsoft Dynamics 365.

Agenda

Production life cycle

- Create

- Estimate

- Schedule (Operations and Job Scheduling)

- Release

- Start

- Report as Finished

- End

Step by step process

Create

- Go to the production module and manually create the production order for the finished good item Mobile. The top floor team is responsible to create the production order.

- The delivery date indicates when the production order should end to deliver on time. This date can be used in the scheduling process. For example, we can schedule the order backward from the delivery date.

- The system will automatically pick the active BOM and Route, business users can also change the BOM and Route if required.

Estimate

- The next step is to estimate the production order. The estimation will run to calculate the estimated cost for production order material, process, etc.

- This page displays the cost breakdown. For example, you can view the total cost price per unit for the finished product in the first row. The subsequent rows contain costs according to the bill of materials, production route, and indirect costs.

- The top floor team is responsible to estimate the production order.

Scheduling

Scheduling will be used to plan the production process, in Microsoft Dynamics D365 SCM, we can perform the operation scheduling or job scheduling. The production route will determine the start and ending date and time and also the material required to produce the finished good items.

Operations VS Job Scheduling

- Operations scheduling and job scheduling enable us to schedule multiple productions in the order of their assigned priority; however, they differ in their level of detail. Generally, operations scheduling is used for long-term scheduling at a resource group level, while job scheduling is used for short-term scheduling at a detailed or specific resource level.

- Operations scheduling is calculated based on dates (while also calculating the duration of individual operations), and job scheduling is calculated based on the starting and ending times of individual operations.

Scheduling Directions

There are two major options for scheduling direction in D365.

- Forward from scheduling date

- Backward from scheduling date

Forward from scheduling date

The Forward from scheduling date option (forward scheduling) will be used to schedule the production to start at the earliest date possible. The scheduling will run forward in time and the production will be scheduled to end at the earliest possible end date.

If machine capacity is booked today, this scheduling option will schedule production to start at a time when machine capacity is free (earliest start date). It will then plan production forward in time from this date to reach the earliest possible end date.

This option is also known as the “push” method because production is pushed through the process. You can schedule production to start today, tomorrow, or at any date in the future. Today’s date is set up for the Scheduling date by default.

Backward from scheduling date

If we use Backward from the scheduling date (backward scheduling), Supply Chain Management schedules the production to begin as late as possible, without jeopardizing the target deadline from being met.

Backward scheduling is based on the date that the production must be completed (latest end-date) rather than when it is started. The schedule is prepared by counting backward to the latest possible date that the production can be started.

This option is also known as the “pull” method because production is driven by the end date and pulled back through the production process to its start date.

Let’s schedule the production for Operation Scheduling first.

Select the scheduling direction “Back from the delivery date” and Press ok.

Capacity Reservation

In the Capacity reservation form, we can see that all the operations are scheduled for the resources by date, there is no start and end time. If you need a start and end time, you need to select job scheduling.

Since we selected the scheduling direction “Backward from the delivery date”, System will make sure that the finished good must be produced on 10th March maximum. (Delivery date for this production order is 10th March). Though the resources are available for scheduling on 8th March, the system will not schedule it on 8th, it will delay the production for one day based on my delivery date.

Operations Scheduling “Forward from today”

I have also run the simulation for scheduling direction “Forward from today”, in this case, the system has scheduled the resource from 8th March and finished good will be ready on 9th March. Forward from today option will be used to schedule the production as soon as the resources are available.

Job Scheduling

Based on the route for the finished good items, Job scheduling splits the different operations into their specific jobs, which are planned in detail for each of the resources.

Job Scheduling – Forward from today

Select the scheduling direction “Forward from today”. Press ok.

Job scheduled

In the below screen, the system has updated the production order status to “Scheduled”. Also, the scheduling status is “Job scheduled”.

Job Scheduling Capacity Reservation

In the below screenshot we can see that the jobs are scheduled by the system from 8th March, the resources (machines) are scheduled on 8th and 9th March. Also, we can see the start and end times.