In today’s complex and fast-paced supply chain environment, traditional planning methods often fail to manage variability and ensure timely product availability. Microsoft Dynamics 365 Finance & Operations (F&O) offers robust planning tools, but integrating modern methodologies like Demand-Driven Material Requirements Planning (DDMRP) can further improve responsiveness and stability. Organizations can buffer against demand fluctuations and streamline material flow by incorporating decoupling points.

This blog explores how combining Demand Driven MRP principles with Dynamics 365 F&O enhances supply chain planning and leads to more agile, demand-driven operations.

We will walk you through the key system configurations required to enable DDMRP, including how to set up decoupling points, buffers, and planning parameters that support a demand-driven approach within the Dynamics 365 environment.

Explore part 1: Demand-driven MRP in Dynamics 365 F&O for smarter inventory optimization.

DDMRP in action

Demand-Driven Material Requirements Planning in Dynamics 365 Finance and Operations doesn’t replace existing planning functionality; it’s integrated with the existing master planning setup and introduces a new coverage code of type “Decoupling point.”

Throughout this demonstration of DDMRP, we will be using the use case of a finished good item, i.e., Perfume OUD-75ml (SAPG-FG-01), having a cumulative lead time of 28 days, since a raw material, namely Fragrance concentrate (SAPG-RM-05), has a lead time of 21 days. We will use “Decoupling point coverage group for Fragrance concentrate (SAPG-RM-05) which will decouple the finished good bill of material (BOM) to get two independent structures. This approach resulted in a reduction of lead time to 06 days. The steps below explain how it can be done in Dynamics 365 Finance and Operations.

Before proceeding, we will perform pre-requisite configurations in D365FO to help arrive at the correct planning calculation using Demand Driven MRP in D365.

Pre-requisites to consider

- Set up a Coverage group of type “Decoupling point”

- Set up the Demand forecast for items (i.e., based on the sales plan)

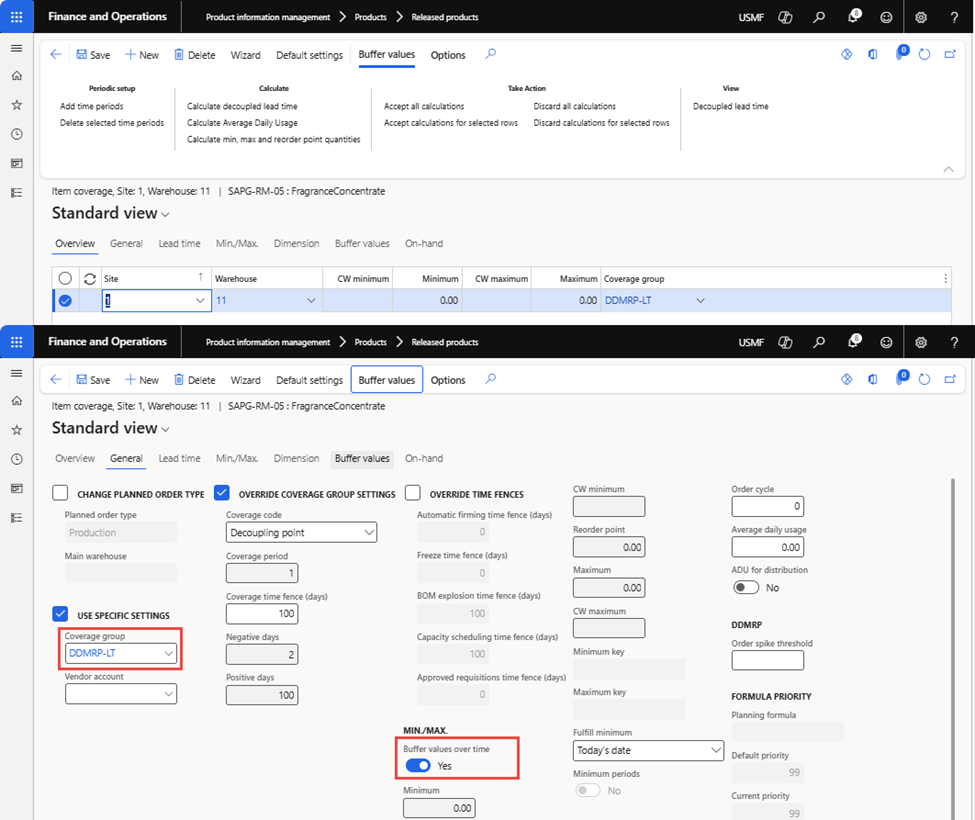

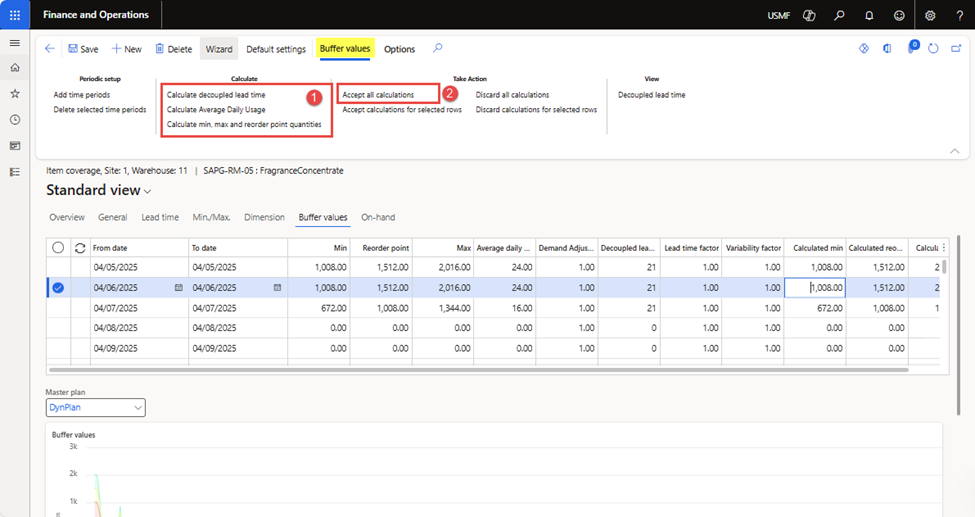

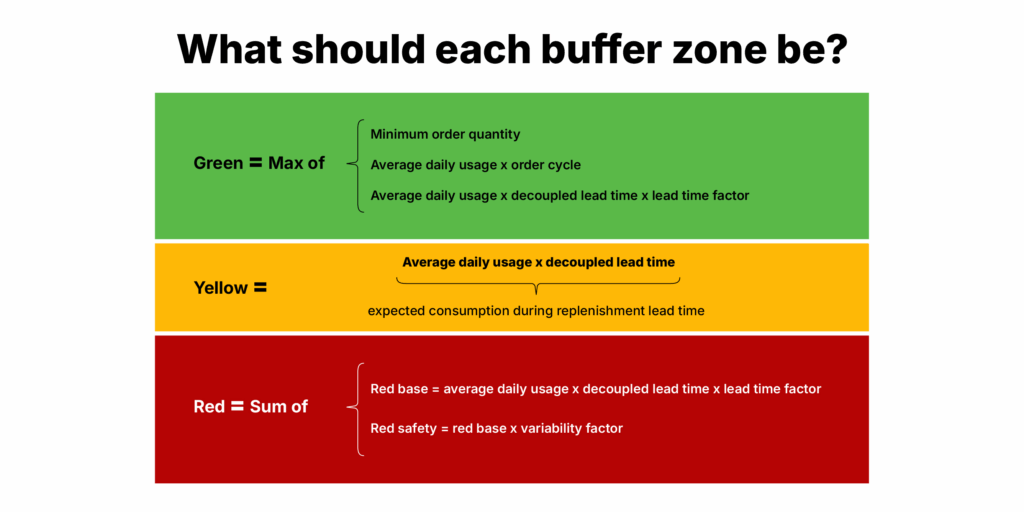

- Set up a “Decoupling point” coverage group with Item(s) to decouple item supplies with longer lead time and calculate Buffer values for item(s) using the following functions:

a. Decoupled lead-time

b. Average daily usage

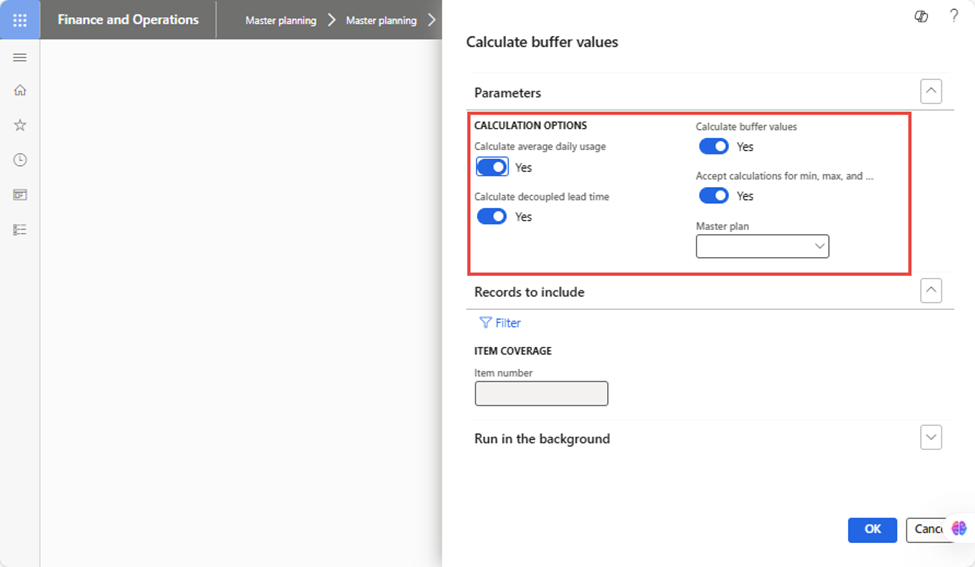

c. Min, max, and reorder point quantities - Average Daily usage & Buffer values calculation

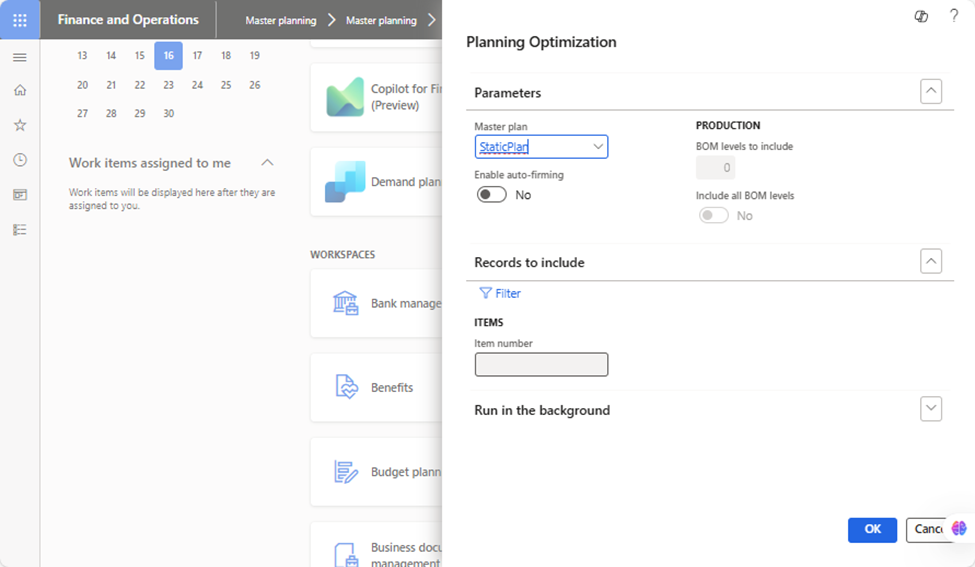

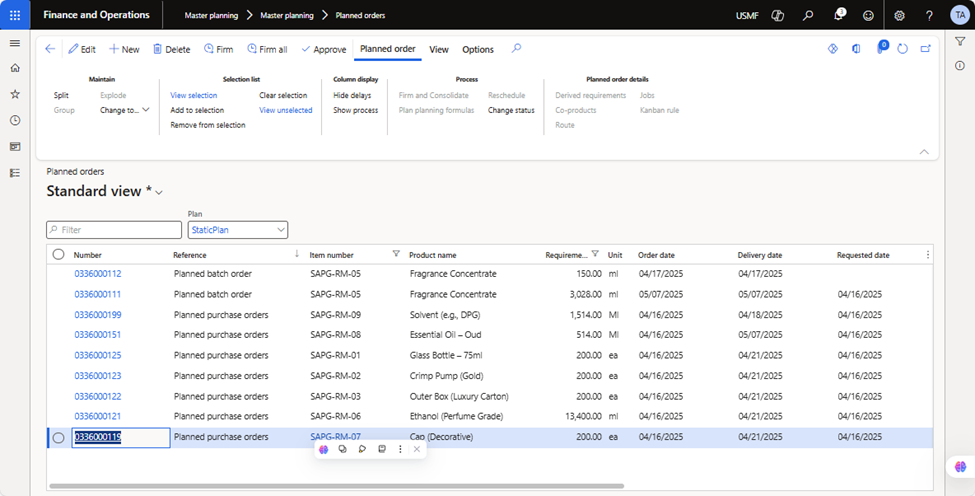

- Run master planning for decoupled item(s)

Coverage group

In Microsoft Dynamics 365 Finance and Operations, decoupling and lead time factors are managed using a coverage group of type “Decoupling point” and linking it with items to decouple material demand from supplies. If an item has no coverage code defined, then a “Coverage group” defined with master planning parameters will be used.

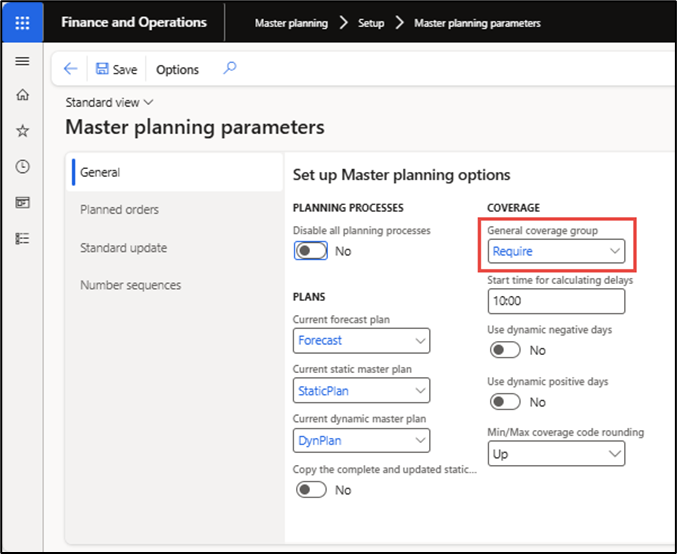

Figure 1: Master planning parameters showing the value of “General coverage group”

Therefore, we will create a new coverage group of type “Decoupling point.” Next, identify items with longer lead times and associate the newly created coverage group with those items using the steps listed below.

- Open the D365FO application

- Go to Master planning > Setup > Coverage > Coverage groups

- Create a new coverage group named “DDMRP_LT”

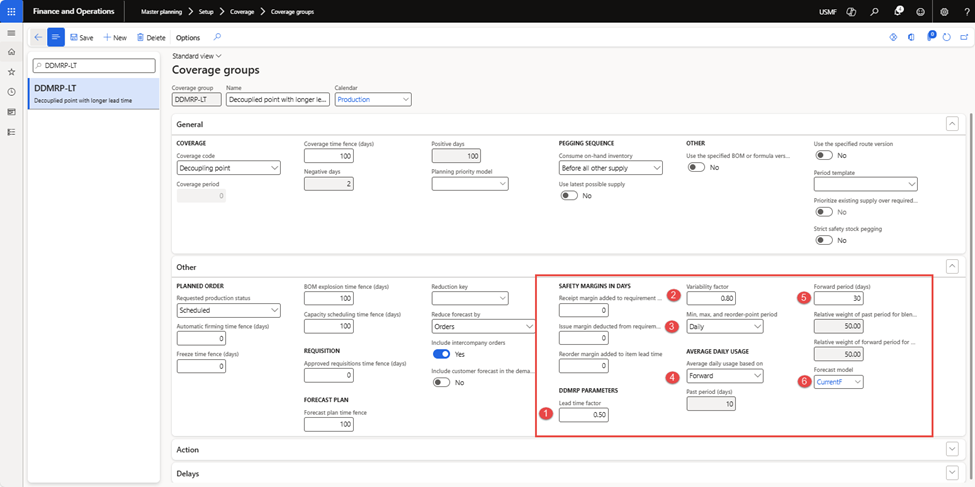

- Set values as follows (see Figure 2 below):

a. Coverage code = Decoupling point

b. Time fence = 100 days

c. Lead time factor = 0.50

d. Variability factor = 0.80 – this defines

e. Average daily usage = “Forward”- this means we want the system to calculate average daily usage based on future demand.

f. Forward days = 10 – this value defines the future demand that the system shall consider to calculate the Average daily usage

g. Forecast model = CurrentF

Figure 2: Coverage group of code type “Decoupling point”

Setup Item(s) Demand forecast

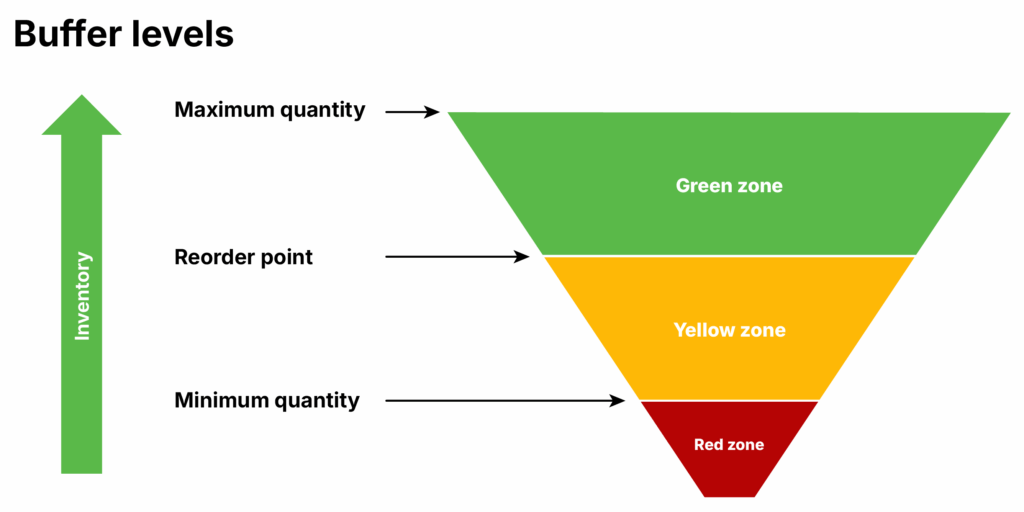

In Microsoft Dynamics 365 for Finance and Operations, we can sense the demands of items from actual customer orders or use the sales plan. We will use the Demand Forecast function to define sales demand quantities per item and location for this demonstration. Using the forecasted sales demand, the system will calculate and suggest buffer stock values, including Minimum, maximum, and reorder points, which we will review and accept or reject while setting up a coverage group with items.

Further insights: How does the Demand Planning App in D365 SCM drive forecast accuracy and smarter planning?

Here are the steps to get started with:

- Open the D365FO application

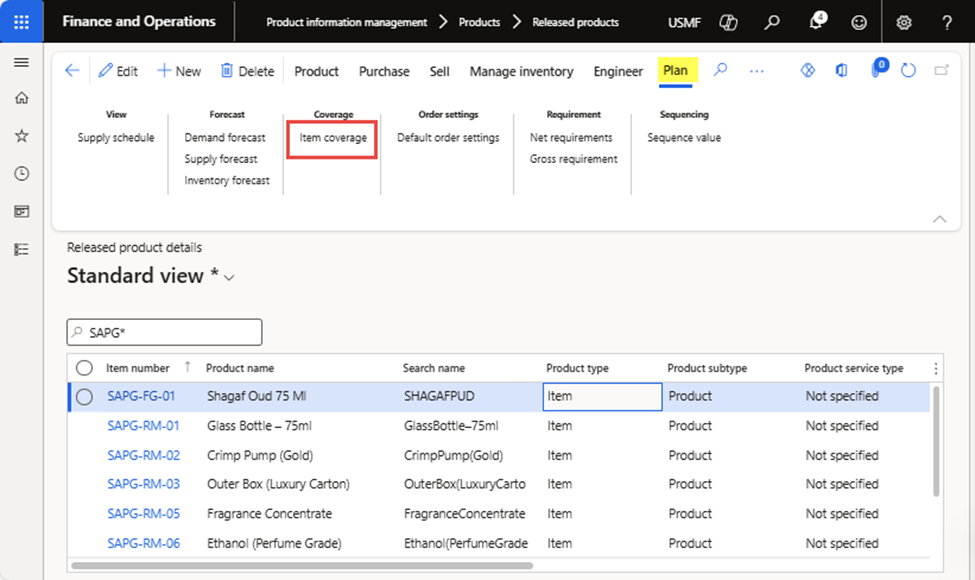

- Go to Product information management > Product > Release products

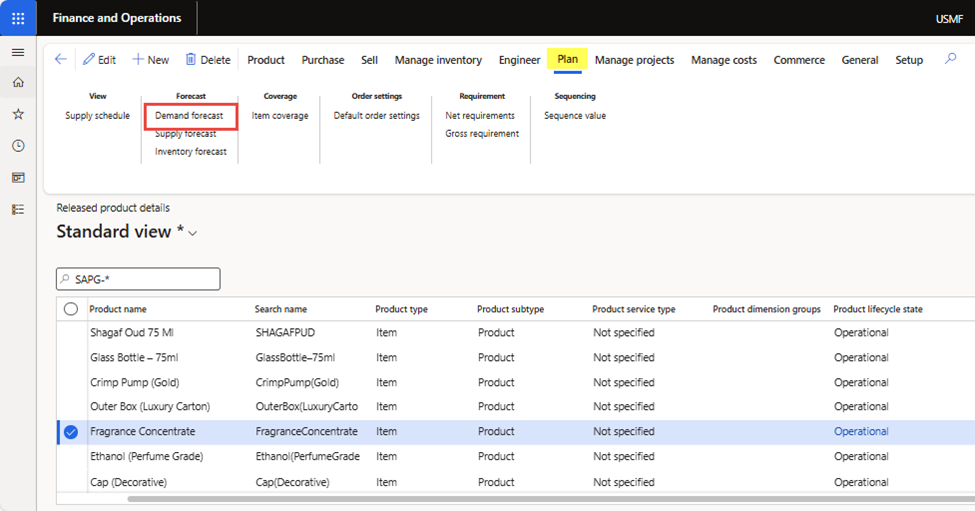

- Select the SAPG-RM-05 product and then click Plan > Forecast > Demand forecast. A new form named Demand forecast will open, where you can define the future demand for items for different periods (see Figure 3)

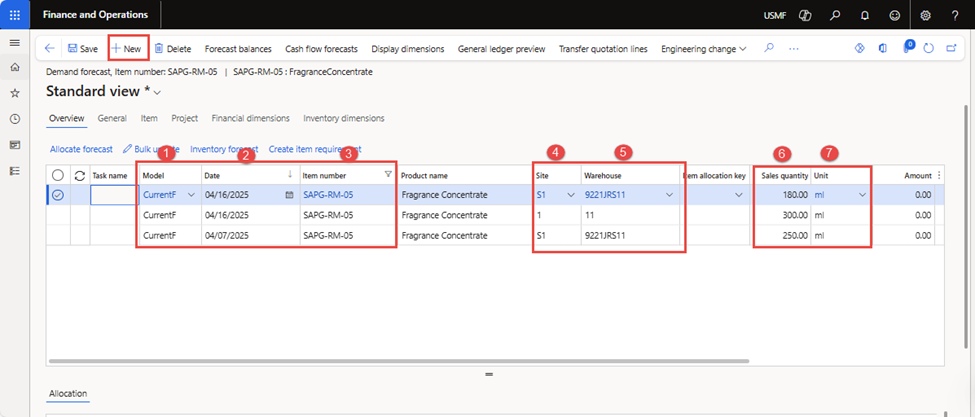

- Click New to enter a new sales forecast line for the selected item and do the following (see Figure 4):

i. Model – Enter “CurrentF” as the forecast model value

ii. Date – Enter the date for which you want to consider the sales forecast

iii. Item Number – Item number will be automatically selected for the sales forecast

iv. Warehouse – Enter Warehouse/location for which sales forecast is being set

v. Sales Quantity – Enter quantity for the item

vi. Unit – enter sales UOM for the forecast item - Repeat steps 3 to 4 to add new sales forecast lines for the latest items.

Figure 3: Shows the “Demand forecast” setup option for released products under Plan > Forecast> Demand forecast

Figure 4: Shows “Demand forecast” lines for “SAPG-RM-05 Fragrance concentrate” item