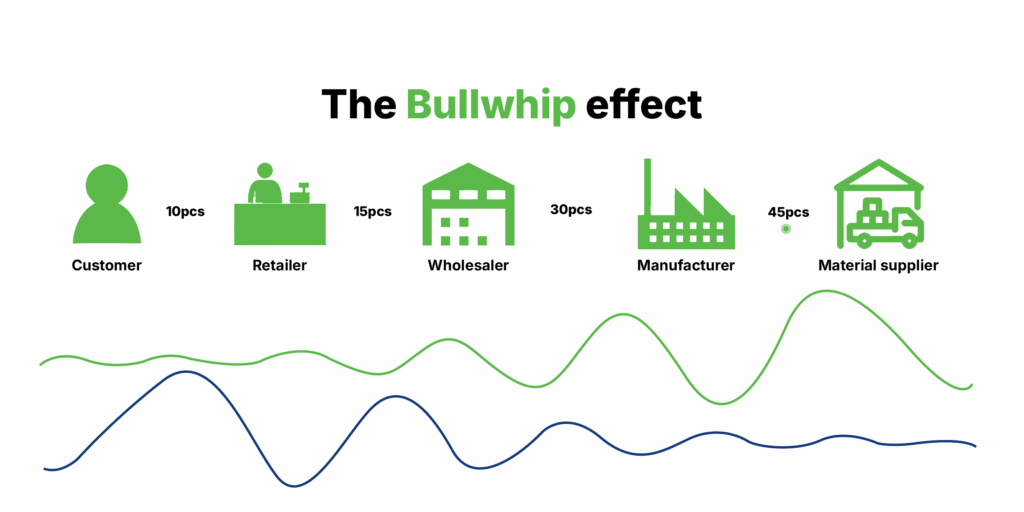

With increasingly complex global supply chains, extended lead times, supply delays, poor forecasting, and unpredictable demand with short lead times, businesses often face inventory imbalances and operational inefficiencies. Traditional Material Requirements Planning (MRP) systems struggle to keep up, leading to frequent stockouts, overstocking, and a reliance on thousands of manual planning actions.

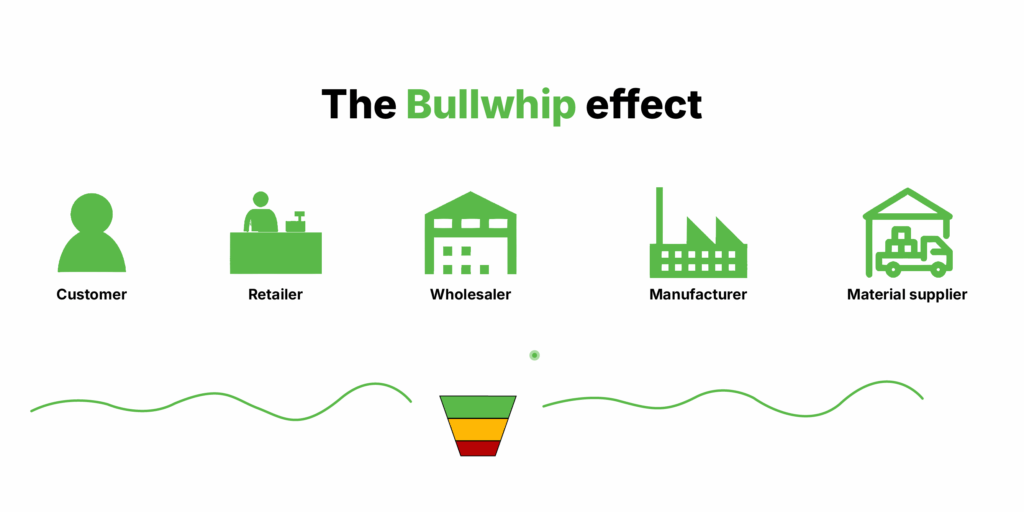

Demand-driven material planning (DDMRP) methodology offers a powerful solution by decoupling supply from demand through strategically placed inventory buffers. This approach minimizes the bullwhip effect, improves material availability, and enables planners to focus on high-impact decisions, resulting in a more responsive and resilient inventory planning process.

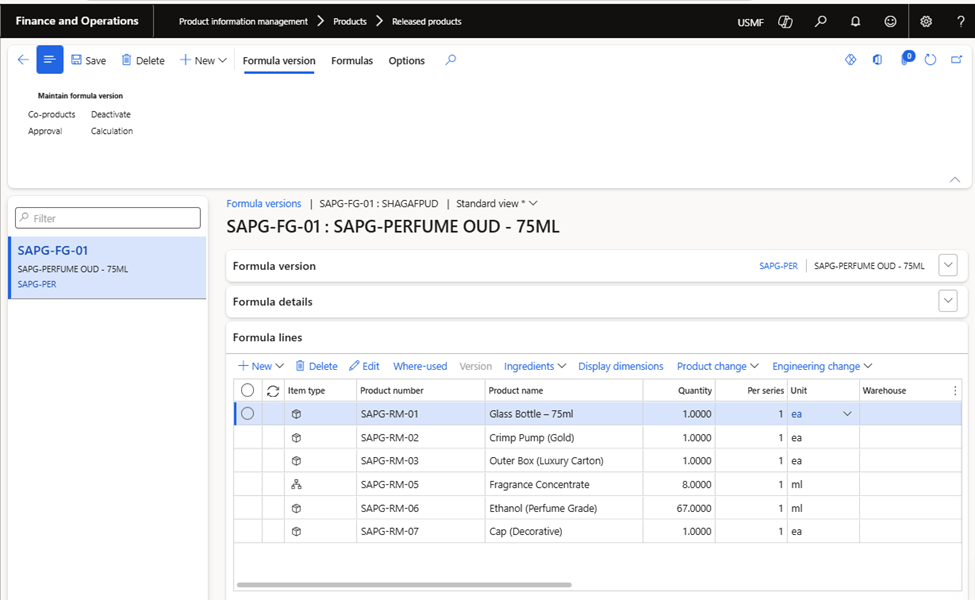

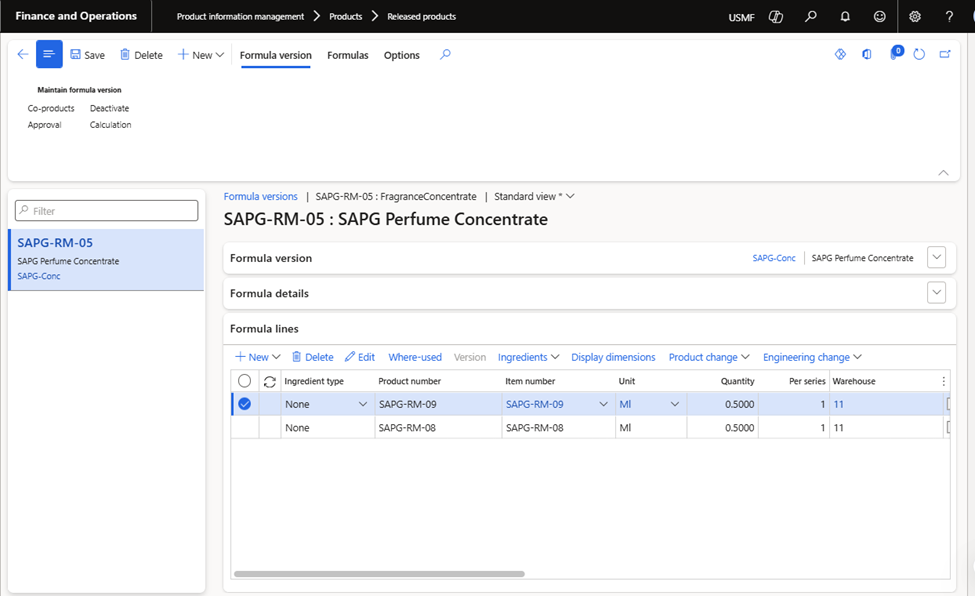

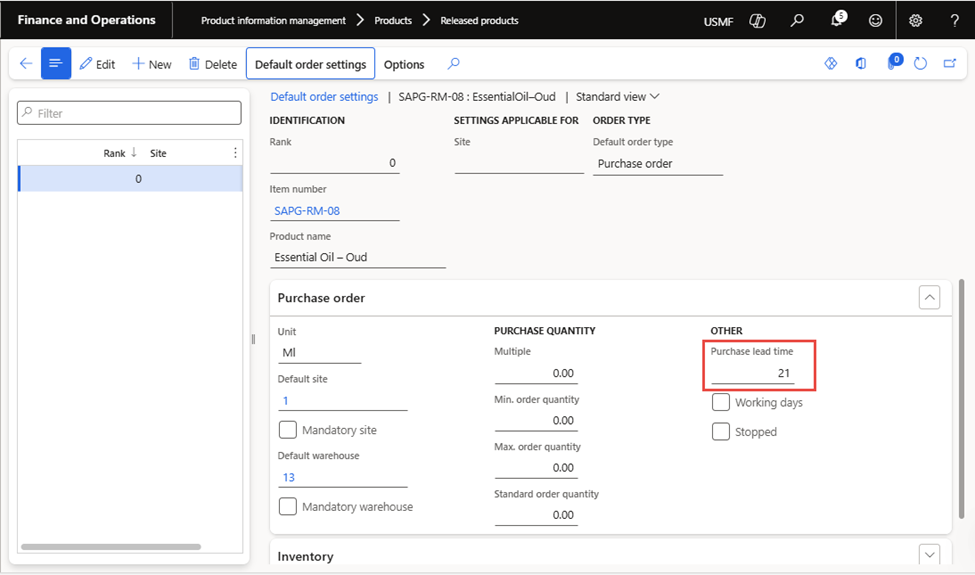

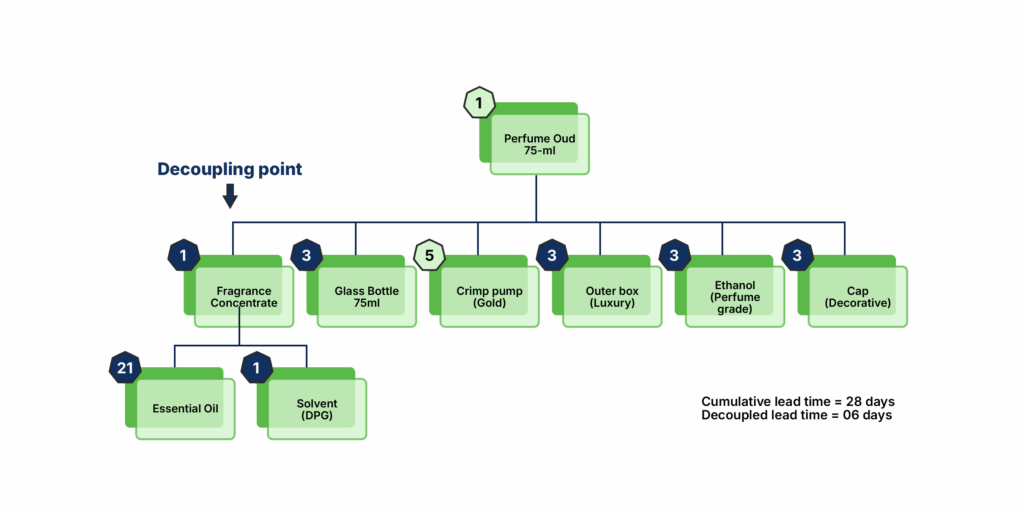

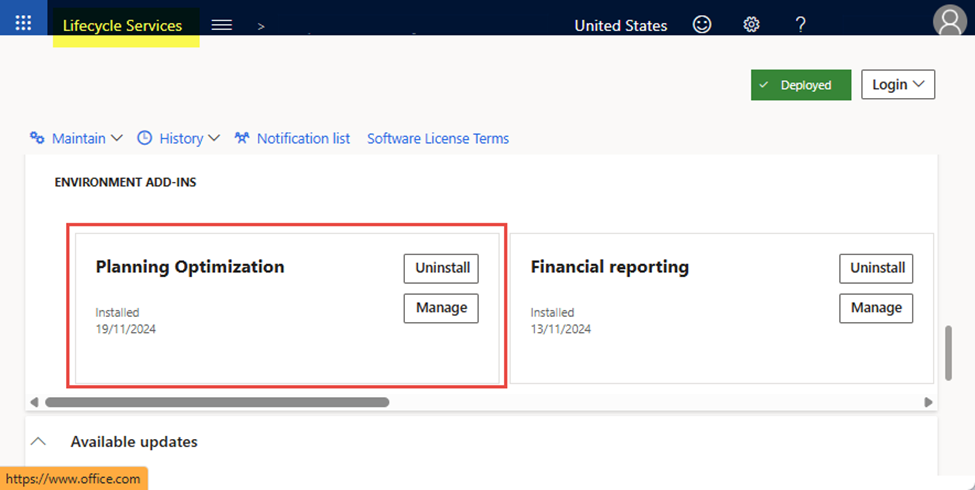

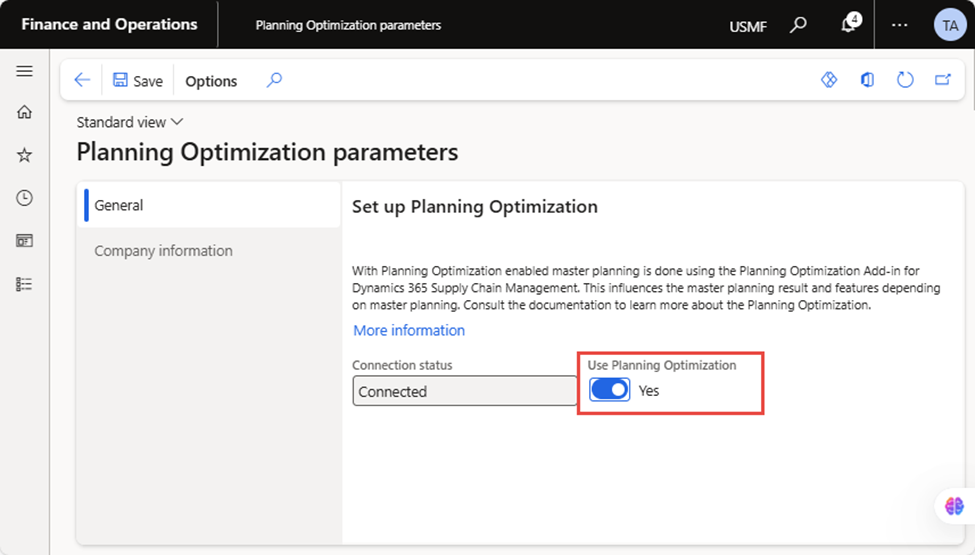

This blog is the first in a two-part series exploring the fundamentals of the Demand Driven MRP methodology and its practical benefits for businesses. Using a real-world scenario involving a finished good with long-lead-time BOM items, we will demonstrate how DDMRP in Dynamics 365 Finance and Operations helps maintain optimal on-hand inventory to meet customer demand with shorter lead times.

What is Demand Driven MRP (DDMRP)?

Demand-driven material planning (DDMRP) is a planning methodology that is based on the decoupling of supply and demand. This decoupling is achieved by setting up decoupling point items.

Demand Driven Institute is the standardization body for the Demand-Driven methodology. It defines demand-driven material planning as “sensing changing customer demand, then adapting planning and production while pulling from suppliers – all in real time!”

Implementing DDMRP, as the demand-driven institutes say, typically yields inventory reductions of 30-45 percent (lowering total supply chain cost) while improving customer service. Many companies want to control their supply chains based on DDMRP principles.

More insights: Learn how Demand Planning features in Dynamics 365 SCM can optimize your supply chain.

Why is it time to rethink inventory planning with DDMRP?

Supply chains have changed tremendously over the past five decades (see Table 1 below). Traditional MRP systems worked perfectly earlier, but Supply chain characteristics like global sourcing, complexity, longer lead times, product complexity, and variable demand have made it more difficult to determine how much to stock and when.

That is where Demand Driven MRP D365 (DDMRP) helps us make the right and more effective decisions, so it is worth exploring. It enables businesses to lead the way by employing buffer zones that protect against supply chain shocks and the ripple effect of unexpected changes in demand. It’s a more adaptable, targeted approach to planning and makes sense in today’s rapidly changing world.

We will discuss the details in the coming sections. Meanwhile, here is an overview of how supply chains have changed over the years:

| Supply Chain Characteristics | 1960s | Today |

| Supply chain complexity | Low | High |

| Product life cycles | Long | Short |

| Customer tolerance times | Long | Short |

| Product complexity | Low | High |

| Product customization | Low | High |

| Product variety | Low | High |

| Long lead time parts | Few | Many |

| Forecast accuracy | High | Low |

| Pressure for less inventory | Low | High |

Table 1: Supply chain and market conditions as defined by the Demand Driven Institute